Pulley Side Lagging

| EXW Price: | US $0.5 - 2 / Piece |

|---|---|

| Min.Order Quantity: | 100 PCS |

| Supply Ability: | 10000PCS per Day |

| Port: | foshan/shzhen/guangzhou |

| Payment Terms: | Trade assurace,L/C,D/A,D/P,T/T,Western Union,MoneyGram |

| Brand | HALLELUJAHBELT |

Holy Bible | A tithe of everything from the land, whether grain from the soil or fruit from the trees, belongs to the LORD;it is holy to the LORD.(Leviticus27:30) |

HALLELUJAHBELT Pulley Side Lagging

With advanced coating machine and other excellent facilities, we are professionally producing PVC&PU,PE light conveyor belts, timing belt, flat belt, plastic modular belt, pvc elevator belt and elevator buckets, which are extremely suitable for light industry such as beer industry,robotics industry,ceramic industry,paper making industry, food industry, textile industry,bulk material handling industry etc.

Specification of Pulley Side Lagging:

Pulley Side Lagging: You Can Buy Various High Quality Pulley Side Lagging for Grain elevator from China Manufacturer

HALLELUJAHBELT company, and we are the best Pulley Side Lagging Supplier and Pulley Side Lagging for Grain elevator Manufacturer in China.

Material: Stainless Steel/Carbon Steel

Features:

- Reduces Abrasive Conditions Between Pulley & Belt

- Lower Belt Tensions for Improved Belt Life

- Fast repair speed, the head pulley can be replaced at time without disassembly on the site

- Virtually Eliminates Belt Slippage, wear-resisting layer adopts the special groove structure, increased coefficient of elevator belt and the head pulley, double the traction

- Significantly reduce the cost of maintenance and replacement frequency, reduce the labor intensity.

- keyword: Pulley Side Lagging

- Customize: Available

Using Recommendations

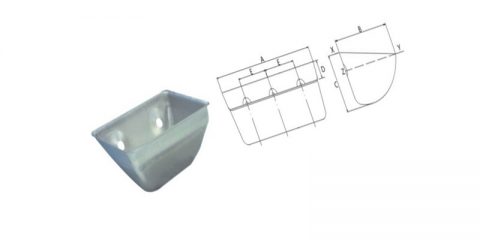

- a) Minimum bucket spacing: bucket projection “B” +25mm

- b) Mounting holes can be customized on request

Parameters for HALLELUJAHBELT Pulley Side Lagging for Bucket elevator

Elevator Buckets Type: 1.D type Elevator Bucket 2.S type Elevator Bucket 3.DS type Elevator Bucket 4.DQ type Elevator Bucket 5.DM type Elevator Bucket(Rice Milling Bucket) 6.DG type Elevator Bucket 7.DH type Elevator Bucket(Drying Bucket) 8.DW type Elevator Bucket 9.DL type Elevator Bucket 10. Steel Elevator Bucket 11.HL Type Inductive Elevator Bucket

Technical Specifications:

1.How to Choose Elevator Bucket Type?

- a)Elevator line speed ≤2.5m/s,gravity discharge and mixed discharge—-Recommend D type or DS type(Deep bottom)

- b)Elevator line speed ≤3.5m/s,high speed centrifugal discharge—-Recommend DQ type(Shallow bottom)

2.Measure an Elevator Bucket & Product Usage Recommendations Note :

Note :

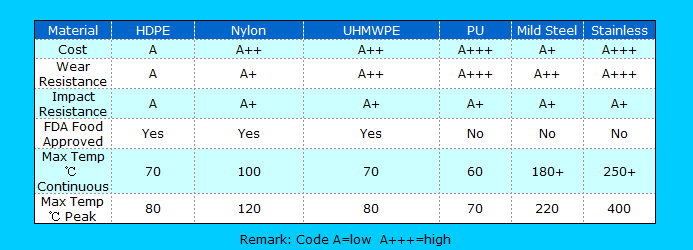

- AA type bucket sizes are based on Nylon. All other type of bucket sizes are based on HDPE. Nylon and PUbucket size are approximately 2% larger than HDPE material bucket.

- Mounting hole dimensions of DM, EU type bucket are strictly according to our size tables, and we can customize mounting holes for all other types of buckets.

- Recommended bucket spacing for DM type bucket is C+2mm; all other bucket types are C+10mm. Actual spacing may adjust then.

- For engineering purposes, HALLELUJAHBELT recommends using Water Level + 10% for applicable designing capacity.

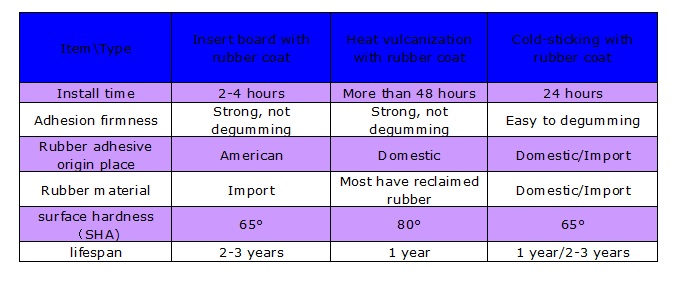

3. Elevator Bucket Material Options

- HDPE: Tough and lexible, suitable for handling grains, foodstuffs, and other products with no sharp edges and material that has a bulk density of less than1g/cm³ .

- Nylon: High impact and abrasion resistance, better heat resistance and are well suited for handling hot, abrasive and sticky products.

- UHMWPE: Extremely abrasion resistance, corrosion resistant, impact absorbing properties, low temperature resistant, sanitary (FDA approved), Non-caking and sticking, now water absorption, light weight properties.Higher cost performance products.

- PU: Extremely abrasion resistance, tough and lexible, and are suitable for handling sharp, cutting and sticky products.

- Mild Steel: General purpose, long life, well suited to agricultural and industrial products.

- Stainless Steel: Food grade, corrosive resistance, suitable for food and high temperature applications.

COMING SOON …………….. THANK YOUR PATIENCE